Model 110

Brushless Slip Ring

One Conductor,

10 Amp

Model 104

Brushless Slip Ring

One Conductor,

4 Amp

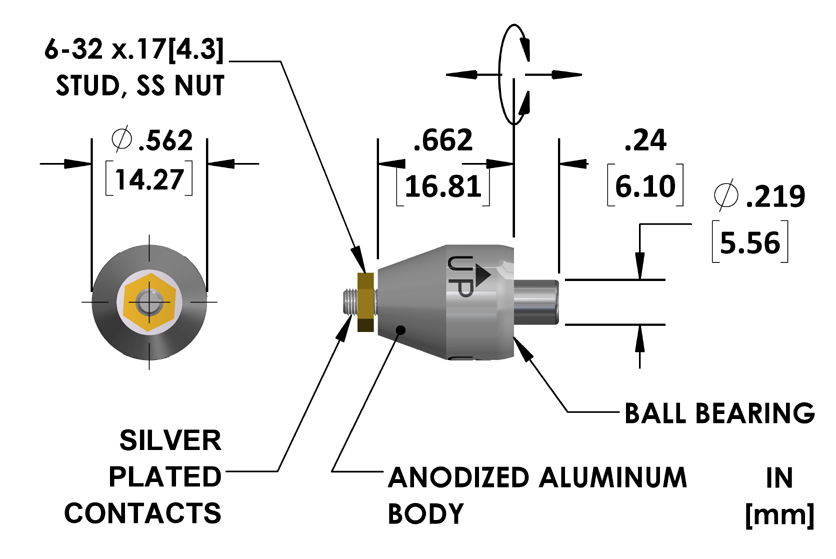

The Mercotac® model 110 brushless slip ring is designed for up to 10A

applications where a single channel is needed. The Mercotac model 104 while

having a lower current rating is designed for higher RPM applications. These

models are intended to be mounted at the bottom of a vertical rotating shaft

or wherever a threaded stud mount or connection is required. Commonly

used in plating, grounding, and static charge applications they are also

suitable for microelectronics, moisture sensing, wire metal fatigue testing,

and more.

Model 110 & 104 Specifications

| Model Number | No. of Conductors | Voltage Range AC/DC | Current Rating @240VAC (amp.) | Max. freq. (MHz) | Contact Resist. | Max. RPM | Operating Temperature °F (°C) max./ °F (°C) min. | Typ. Rotation Torque (gm-cm) | Circuit Sep. |

| 104 | 1 | n/a | 4 | 200 | <1mΩ | 7500 | 140 (60) / 45 (7) | < 10 | n/a |

| 104-SS | 1 | n/a | 4 | 200 | <1mΩ | 7500 | 140 (60) / 45 (7) | < 10 | n/a |

| 110 | 1 | n/a | 10 | 200 | <1mΩ | 3600 | 140 (60) / -20 (-29) | 35 | n/a |

| 101-SS | 1 | n/a | 10 | 200 | <1mΩ | 3600 | 140 (60) / -20 (-29) | 35 | n/a |

| 101-SS | 1 | n/a | 10 | 200 | <1mΩ | 1200 | 140 (60) / -20 (-29) | 10 | n/a |

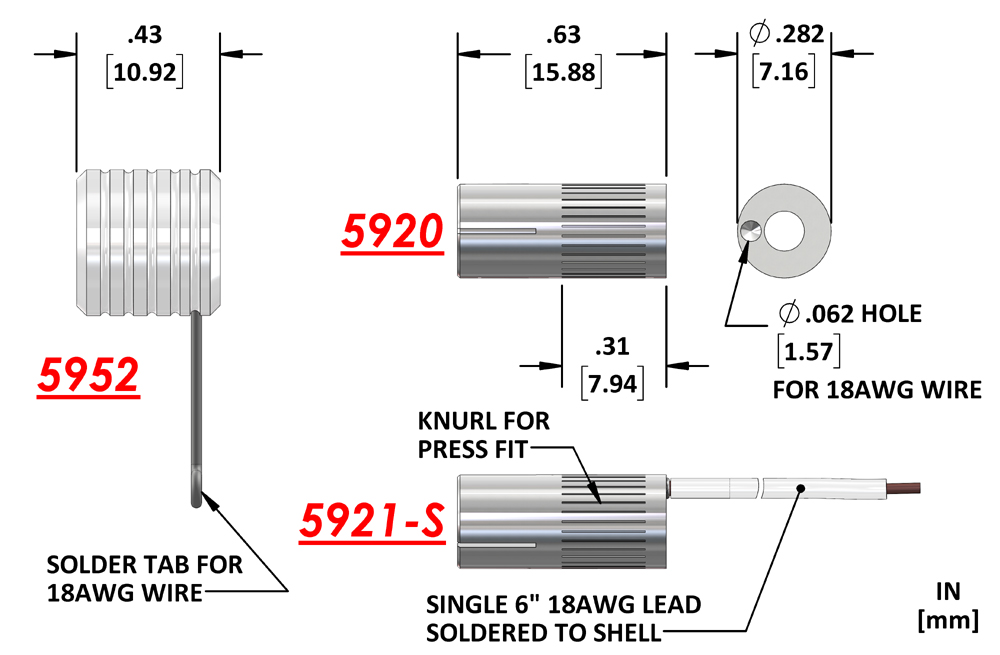

Model 110 & 104 Accessories

5920

one contact receptacle

5921-S

one contact receptacle w/ 6″ wire5952

one contact cap

w/solder lug

55337

ring terminal (12-10 AWG)

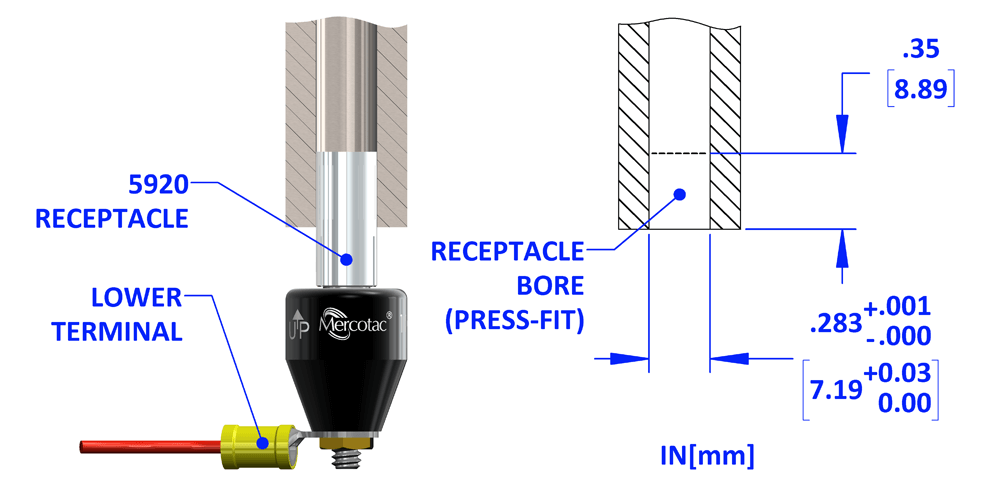

Receptacle used for mounting to rotating device.

Accessories are required for wire connections. Order Separately

Model 110 & 104 Connections

Model 110 & 104 Standard Wire Connections

Model 110 & 104 Suggested Mounting Methods

|

Receptacle Mount Hole Dimensions |

|||

| MODEL | HOLE DIAMETER (Ø) * | DEPTH | |

| 5920, 5921-S | .283″ (7.19) | .35″ (8.89) | |

| *Inch (mm) Tolerance Ø | +.001″ (+.025) | ||

| -.000″ (-.000) | |||

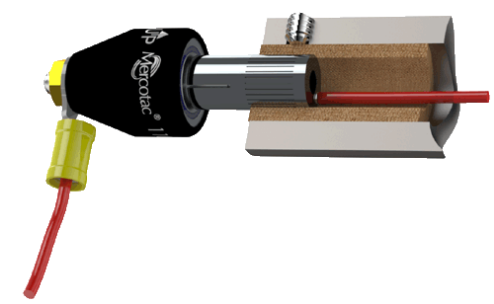

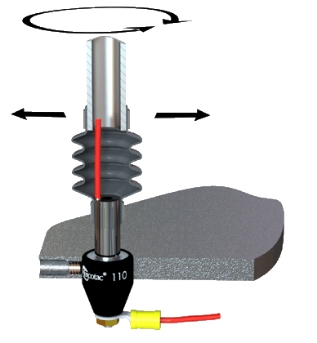

Bottom Mount with Conductive Shaft

Preferred mounting orientation.

Vertical Mount with Electrically

Insulated Shaft

The Mercotac body is electrically hot.

An electrically insulated shaft can isolate it, if needed.

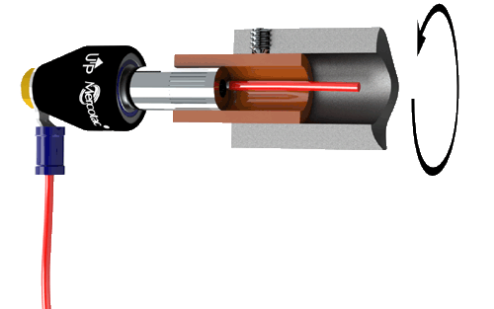

Horizontal Mount with Electrically Insulated Shaft

The Mercotac body is electrically hot. An electrically insulated shaft can isolate it, if needed.

Thermal & Electrically Insulated Horizontal Mount

Use if electrical and thermal insulation is needed

Vibration Isolating Mount

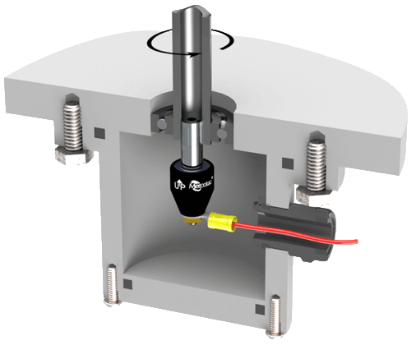

Protective Housing Mount with Conductive Shaft

Installation Notes:

- The up arrow should not point below horizontal

- Do not solder to or bend connector tabs

- Avoid lateral forces and mechanical loads (overly stiff or tight wires)

- Do not rigid mount both ends of connector

- Limit mounting eccentricity (runout / wobble) to .005″ (.13mm)

- Provide overload protection within the circuit

- Avoid vibration and bumping motions